- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Recycled Fabrics, Real Performance: QIYI’s Step Toward a Greener Sports Industry

2025-10-21

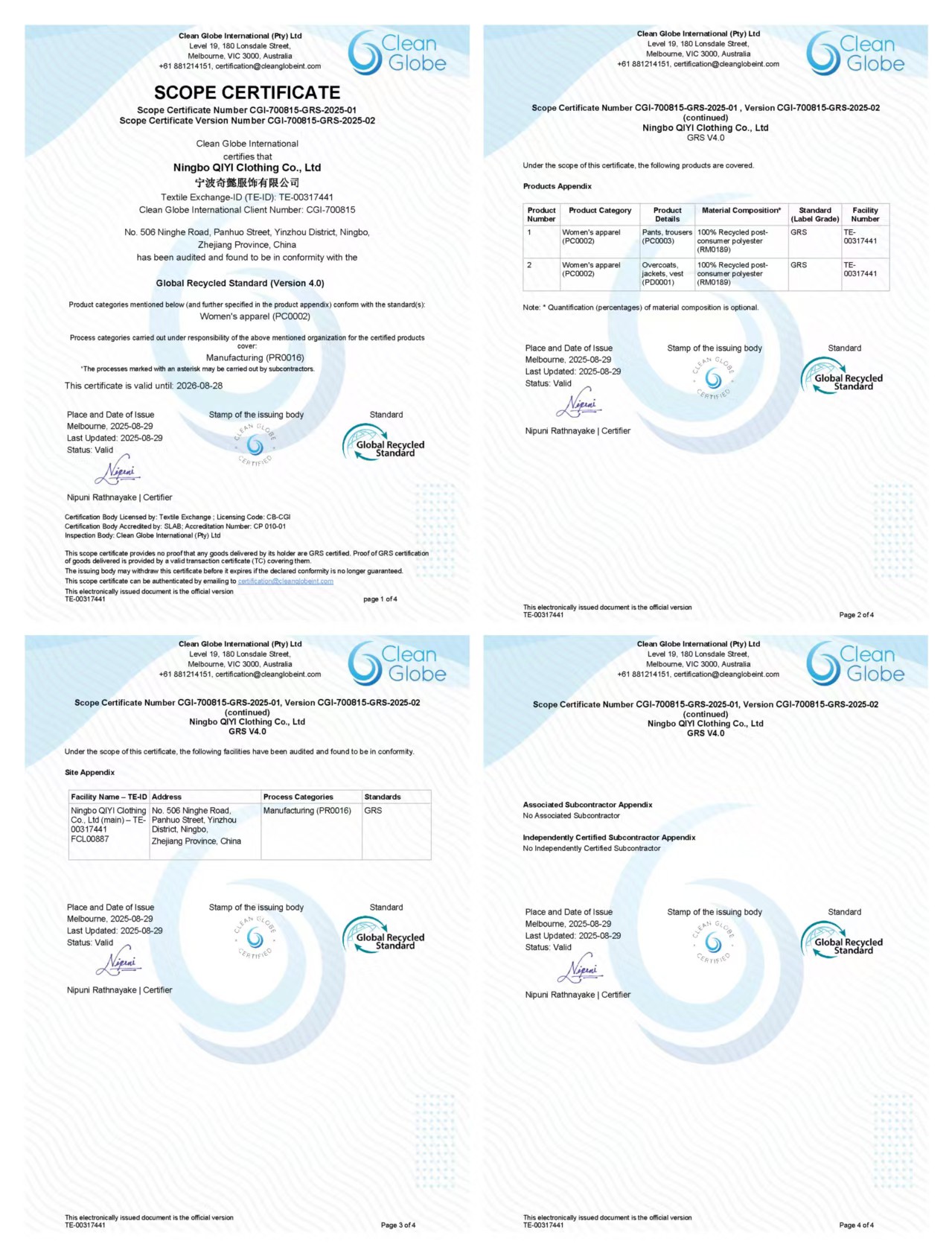

At Ningbo QIYI Clothing, we have always believed that excellent sportswear is not only performance, but also responsibility. As environmental issues gain more and more attention worldwide, we are pleased to apply recycled textiles to our production and obtain GRS certification (Global Recycled Standard), which has made significant progress. For us, this honor is not just a title; it is a testament to our untiring dedication to sustainability, openness and excellence.

Our goal has always been clear: to design high-performance, environmentally friendly professional clothing. We are reinventing sustainable performance clothing through investments in cutting-edge technology, environmentally friendly materials and ethical manufacturing.

1. Why We Chose Recycled Fabrics

Fabric is very important in the field of sportswear. It describes the athlete 's emotions, movements and performance. However, with the increase of global production, the pressure on natural resources is also increasing. We realize that by rethinking the materials that form the basis of our products, we may actually make a difference.

Therefore, we began to turn to the recovery of 100 % polyester from post-consumer plastic bottles. Materials that may have been entangled in landfills or oceans have been given new life every metre. A recycled sweatshirt can often save 5 to 6 plastic bottles, which is a small amount, and when thousands of clothes are used, its number will increase.

In addition to environmental protection, our recycled polyester textiles are also effective. They have the same technical advantages as native polyesters, including light weight, air permeability, and moisture absorption and perspiration, but their impact on the environment is much lower. These textiles show that sustainability and style can coexist harmoniously by combining vibrant colors and long-lasting durability with our sublimation printing process.

We want to go beyond language, so we strive to achieve GRS certification. This international standard demonstrates the ethical, social, environmental and chemical standards of our supply chain, as well as the recycled materials used in our products. It ensures that every piece of sportswear we produce, from fabric acquisition to final sewing, truly meets global sustainability standards.

2. Balancing Performance with Responsibility

Many people still believe that ' eco-friendliness ' means sacrificing performance or quality. Our aim is to prove the opposite. Whether it is a baseball shirt, a football uniform, or a bicycle sweatshirt, every piece of clothing we make must comply with our strict standards for comfort, style, and usefulness.

Each recycled fabric is subjected to a rigorous testing process to ensure that it retains its strength, elasticity and color fastness even after multiple washings and long-term use. In addition to the fact that recycled materials are better for the environment, athletes who often wear our products cannot distinguish them.

Advanced four-directional stretch polyester blends were used in our production; make them move organically with the body while maintaining shape. In order to keep the athletes cool and dry during strenuous exercise, we also used a moisture absorption treatment to remove skin sweating.

In addition to functionality, we focus on small things, including breathable grid areas, ergonomic panel design, and soft seams that are important in the real environment. Our view includes these specific elements: Sustainability should improve performance rather than reduce performance.

By combining technological innovations with recycled fabrics, we make sportswear that athletes are proud of, not only because it looks good, but also because it performs well.

3. Our Ongoing Journey Toward a Greener Future

Becoming a sustainable manufacturer is a continuous process, not a one-time achievement. Although obtaining our GRS certification is an important achievement, it is only the beginning. We are constantly looking for new ways to improve energy efficiency, reduce waste, and expand our choice of environmentally friendly items.

For example, we updated the sublimation printing machinery, using water-based, non-toxic inks, reducing the use of water and removing dangerous chemicals. In order to reduce the waste of the remaining fabric, we also improved the cutting process and installed an energy-saving hot press.

We are educating our factory employees on sustainable measures such as ethical packaging and careful material handling. Building a culture of production that respects people and the environment is the common goal of every worker, designer and technician.

In addition, we have begun to cooperate with international sportswear companies that respect sustainability and openness. Nowadays, many of our customers are asking for certified recycled materials for their collections, and we 're honored to help them achieve their vision. Encouragingly, environmental awareness is becoming a standard expectation of the entire sports industry, rather than the aspirations of a few people.

At Ningbo QIYI Clothing, we regard sustainable development as an opportunity to lead, motivate and innovate, rather than a responsibility. We realize that tomorrow 's clothes are shaped by what we do today. Therefore, we continue to invest in more environmentally friendly materials, more efficient production technology, and better ways to serve our customers and the environment.

Leading with Purpose

Our goal for the future is still the same: to create athletic gear that feels good, works well, and contributes to a better environment. Although there is still a long way to go, every decision we make—every recycled fiber, eco-friendly print, and careful design—brings us one step closer to our goal.

Our GRS certification is evidence that there is no need to sacrifice environmental impacts for real performance. Light, sturdy, stylish clothing can be produced, both responsible and traceable.

As we expand, we want to encourage more brands and partners to join us to create a more powerful and environmentally friendly sports sector. Because we at Ningbo QIYI Clothing believe that sustainability is as much a future performance as fashion.